Production Lines

Trained Technicians

sqft Monthly Production Capacity

sqft Manufacturing Area

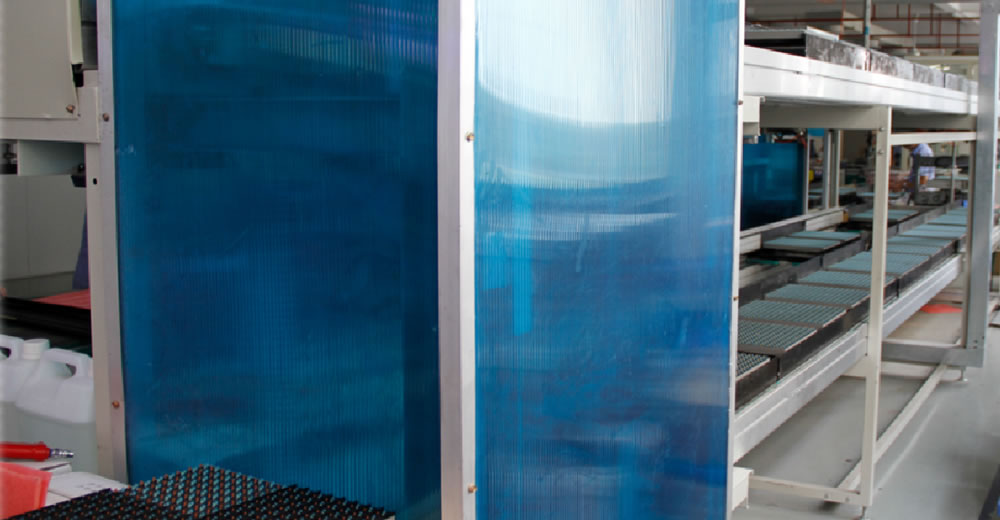

A Glance at Maxlumin’s Factory

An LED Panel’s Journey, from Dots to Pictures

Ever wonder what an LED display needs to go through for excellent visual performance and a long product life? Here are the 5 major crucial processes in Maxlumin.

SMD/DIP Workshop

This is where we precisely plug LEDs into a PCB using either SMD or DIP. We print solder paste cream on the PCB, then use reflow soldering to connect LEDs to the PCB. AOI tests examines the PCB for defects.

Electronics Workshop

At this phase, we solder all the electronics components to the PCB to make it an LED module. Conformal coating is applied to the PCB while silicone glue seals the LEDs for protection from the environment and corrosion. When needed, a face mask is put on the LEDs for extra layer of protection. Functional testing makes sure the LED module works properly.

Metal Sheet Workshop

For customized products, we have our own metal sheet workshop, allowing us to design and produce the metal frames of LED display in any size and shape.

Assembly Workshop

We combine several LED modules with frame, cables, power supplies, control system and other accessories into an LED panel. LED display for outdoor use needs waterproof treatment on the entire frame. Each and every LED panel must pass aging tests to ensure the longevity.

Packaging

Now, your LED display is ready to go. We pack the LED display with highly protective foams and boxes to keep them safe and secure during shipping.

Consult Your Custom LED Display Experts

We offer free consultation and solution that exceed your expectation on performance and quality, within your budget.